Our partners

News

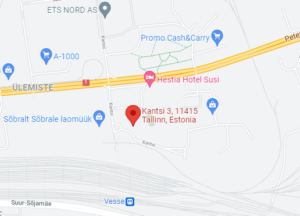

Our Offices

Pick a location on the map to see that offices’ location and contact details.

SIA “InSpe Latvia”

Brīvības gatve 193A,

Riga, Latvia, LV-1039

Orders:

[email protected]

+37128135902

Equipment and material sales:

Matīss Martinovs

+371 20569832

[email protected]

Siser Product Specialist:

Ilva Draudiņa

+371 26895154

[email protected]

Technical Support:

Arnis Bagrovs

+371 28302431

[email protected]

Artūrs Bite

+371 29515648

[email protected]

Reklamis.lt Vilnius

Motorų g. 14, 16 korpusas 3

LT-02190, Vilnius, Lietuva

Managers:

Ieva Čiuladienė:

+370 65937501

[email protected]

Tomas Kalinauskas:

+371 65581010

[email protected]